There is a great variety of three-phase equipment that you can get your hands on! But what if you don’t have a 3-phase power supply?

The costs of installing three-phase utility power are quite high and this is where phase converters come in. The type of converter to use generally should come down to what type of equipment you have and how you are planning to use it.

Moderately to light loads that you are not planning to use up to their full HP potential could probably get away with Static Phase Converters (you can check out an article on Static Phase Converters). If you need to get the most power out of your equipment and/or planning to power the whole shop with it, you will need a Rotary Phase Converter (another article in the link).

The biggest problem with Rotary Phase Converters is that if it is not properly balanced with capacitors, it will produce rough power that could damage your equipment (a common situation, especially for DIY fans). Digital Rotary Phase Converters (CNC compatible) solve this problem by adding a digital controller that provides a voltage balance within a 2-5% range under 50-60% of the full load.

This is how voltage or phase imbalance reduces the motor’s HP rating:

| Voltage imbalance | Motor derating |

| 1% | 98% |

| 2% | 95% |

| 3% | 88% |

| 4% | 82% |

| 5% | 75% |

Phase imbalance also significantly reduces the life of 3-phase motors and greatly impacts their performance. Unlike other phase converters, Digital Phase Converter (or DPC) can safely and reliably power voltage-sensitive loads like:

- CNC (Computer Numerical Control)

- VFD (Variable Frequency Drive)

- EDM (Electrical Discharge Machine)

This perfectly balanced three-phase voltage equipment offers the safe and efficient operation of any 3-phase load within its capacity, which includes (but is not limited to):

- CNC equipment

- Woodworking equipment

- Metalworking equipment

- Industrial machinery

- Agricultural machinery

- Foodservice equipment

- Irrigation systems

- HVAC equipment

- Cranes

- Submersible pumps

- Sawmills

- Elevators

Digital Phase Converters come in two types. They are:

Rotary Digital Phase Converter. This one comes with an idler motor and electronically advanced phase balancing systems, which makes it great for voltage-sensitive applications like CNC.

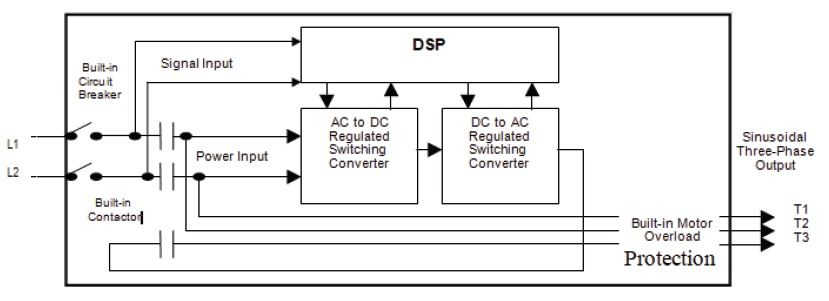

Solid State Digital Phase Converter. This one does NOT come with an idler motor. It uses AC/DC and DC/AC conversion systems in order to give you a third leg of power.

Digital Phase Converter uses a double conversion technique where the input rectifier (which consists of IGBTs in series with inductors) converts AC (Alternate Current) power from utilities into DC current and then back to the AC. Insulated Gate Bipolar Transistors (IGBTs) are controlled by software in the DSP (Digital Signal Processor).

The Digital Signal Processor (DSP) is a microprocessor that controls the whole phase conversion process. Its job is to monitor the input and output modules and maintain balance within three phases at all times.

DSP also serves a function of a surge protector and will shut down if over-voltage is detected. Voltage balance across three legs and a sine-wave output is a good formula for powering safely even the most sensitive equipment.

These types of converters generally operate with 95-98% efficiency.