Why do we need phase converter and what does it do

Phase converters are mostly used to convert the single-phase to three-phase. Most of the commercial and industrial electrical equipment need three-phase power, small and large customers such as residential, rural businesses may not have access to a three-phase power or they don’t want to pay for the extra cost of three-phase service. Many locations are still supplied with single-phase power and local power utilities will not allow any suggestion for additional lines to an unserved location. Most of the single-phase users like to use three-phase for their equipment because the three-phase power output has better quality and it will allow the three-phase equipment to run smoothly. The two main types of single-phase to three-phase converters are static and rotary phase converters. So in order to operate three-phase equipment in a single-phase power, we need to use a phase converter.

What is a three-phase power and how a single phase is different from three phase

What are the methods to convert single phase to three-phase drive system

A wide variety of commercial industrial and electrical equipment needs three-phase power, electric utilities do not use three-phase power because it costs much higher than the single-phase so in order to use the three-phase power single-phase electric power is converted into three-phase power with the help of phase converters like static, rotary and variable frequency drives.

What is a static phase converter and what does it do

A static phase converter is made up of two components a voltage-sensitive relay and one or more capacitor, the relay is used to switch between the two capacitors once the motor has come up to speed. These phase converters are inexpensive and they can only be used on three-phase motor loads. They make use of the idea that a three-phase motor can be started by using a capacitor in series with the third terminal of the motor. Static phase converters can be used to start and run most machines used in a home shop, these type of converters are not suitable to run CNC equipment or any machinery that needs precision in its power supply. It is best to use a static converter to start and run a rotary phase converter.

How does a static phase converter work

Static converters have two components, a voltage-sensitive relay and a standard capacitor connected to the motor application. The capacitor will delay the waveform during the start-up of the motor application. The relay will disconnect this start capacitor after the motor has started, and from this point, the motor will continue turning on the single-phase supply. Motors that operate on a static phase converter will produce about 50-60 percent of the nameplate power, so the motor performance is poor while using a static phase converter. The power can be increased by adding another run capacitor to this design. The start-up capacitor is used only to start the motor and then it is switched out completely. While the run capacitor is always in the circuit and it balances the voltages at one load rating.

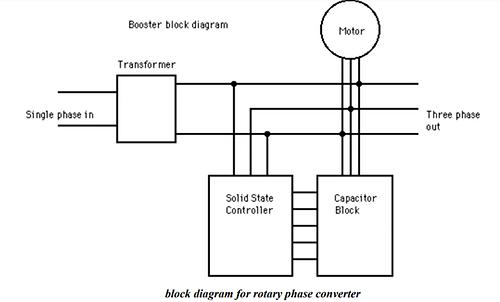

What is a rotary phase converter and what does it do

A rotary phase converter is an electrical machine that can produce three-phase electrical power from a single-phase power. So by using a rotary phase converter, we can run three-phase electric loads in a single-phase power. These phase converters isolate the generated three-phase power from the single-phase supply and balance the three-phase output. Rotary phase converters can provide reliable and efficient three-phase power.

How does a rotary phase converter work

If we add an idle running motor to a static converter, then we have a rotary converter the added motor compensate some of the weakness of the static converter and helps to extend the range of motor sizes and load. This device consists of a three-phase motor and a bank of capacitors wired together to act as a single large capacitor.

Two of the leads of the motor are connected to the single-phase power source and the third lead is connected to the motor is connected in series to the capacitor bank and it is connected to one of the single-phase inputs. Phase converters output leads are connected across the motor terminals. The internal motor will remain inactive during average loads and it will work if the loads are not matched with the value of the chosen run capacitor.

What is the difference between the static and rotary phase converters

Rotary motors can run several motors of different sizes, so the rotary motors can be used to run more than one equipment with better efficiency. The rotary phase converter can provide efficient three-phase power. While the static phase converters can’t be used to run more than one equipment and it won’t provide a proper three-phase power so the static converters can’t be used in equipment that needs precision in its power supply.