Sometimes a woodworker will find himself with a 3-phase tool, but his shop only supplies single phase, 240 volt power. 3-phase motors are common for industrial grade tools, as their efficiency is higher than their single phase counterparts. In order to operate a 3-phase motor on single phase power, we need to make an artificial three phase system. This is accomplished by using a phase converter.

The phase converter will artificially generate the third leg of a three phase system from the two poles of a single phase system. This is not a perfect transformation, but it does get the job done. There are two types of phase converters: the static phase converter, and the rotary phase converter. The rotary phase converter is built using a static phase converter, plus an idler motor.

Balanced Static Phase Converter

The static phase converter is the basic building block for any phase converter, and so it makes sense to start with that. With the static phase converter, the motor will only receive about 80% of its normal operating power. Additionally, you need a separate static phase converter for each three phase motor. These are the primary drawbacks to the static phase converter. However, the static phase converter is very simple to build. This loss of power is balanced by the lower cost of the static phase converter. The significant cost savings is why static converters are so popular.

The drawing above shows a balanced static phase converter with a starting circuit. The starting circuit provides enough current to the motor to get it started, but then must be disconnected to prevent too much current from flowing through the motor after it starts. There are more rudimentary phase converters, but this design provides better performance with lower running currents.

Getting Started

The first step is to select the capacitor sizes that will be needed. This is generally just trial and error, as the capacitor sizes will depend on the motor. I went to an electronic surplus store and located several capacitors for a couple of dollars each. These capacitors should be rated for at least 250 volts AC.

At the surplus store, I located capacitors ranging from 1, 3, 5, 10, 12.5, 15, and 20 microfarads in the 250 volt range. What you will want to do, is get several capacitors of different sizes so you can fine tune the converter. Keep in mind that you can make a capacitor smaller or larger by combining it with other capacitors. Two capacitors connected in parallel will add to each other, and two capacitors in series will “get smaller”.

Explaining how we add capacitors together is a little complex, so I am hoping that most of this can be understood by example. From the lefthand circuit in drawing above, two 10 uF caps in parallel will total 20 uF. We just add their values together. In the next circuit, we have two capacitors in series. Two 10 uF caps in series will total 5 uF. For series connections, we add their reciprocal values, and then take the reciprocal of that. For combination series/parallel circuits, we look at the circuit as two separate problems. In the next sample, we have two caps in series giving us 5 uF as before, which is then in parallel with another cap, so the total is 15 uF. In the last sample, we have two caps in parallel giving us 20 uF, which is then in series with another, and the result is 6.6 uF. Using these various combinations, we can get nearly any size capacitor we want. I used 10 uF capacitors for this example, but they don’t need to be the same size. Take the third sample as an example: this would be the same as a parallel combination of a 5 uF and a 10 uF.

I have to admit, that when I bought capacitors for the lathe, I was way off the first time. I picked up a bunch of 20 uF caps, but these were too large. Because I bought enough of these to build converters for two lathes, I had enough of them to make some complex combinations during the initial sizing. After I found out the final sizes, I went back to the store and picked up smaller capacitors for the final assembly. If you think about it, even making a mistake in your initial purchase is still cheaper than buying a store bought phase converter.

Initial Setup

To start out with, I would set up the converter using the numbers provided above. For a 1 Hp converter, I would use 5 & 12 uF caps between the lines, and whatever capacitors are left over are used for the starting circuit. If the 5 and 12 aren’t available, use whatever is close for now. For the initial capacitor sizing, the following rule should be helpful:CL1-L3 = 4 to 5 times the motor horsepower

CL2-L3 = 10 to 15 times the motor horsepower

Cstarter = 40 to 100 microfarads just for testing

For testing purposes, I used a standard light switch to control the starting capacitors. For some of the configurations, I did not have enough capacitors left over to provide a sufficient starter. For these situations, I used a pull-cord (like starting a lawnmower) to get the motor started.

After you have the initial setup, it is time to turn the motor on. Close the switch for the starting circuit, and press the start switch. If the motor takes more than 2 seconds to get up to full speed, shut it down immediately. You can either add another capacitor to the starting circuit, or try using a pull string. If your motor turns backwards, then just reverse the wires on your motor. (At the motor, take any two of the three wires and swap them.) Once the motor is up and running, it is time to fine tune the capacitors.

Tuning the Capacitors

To fine tune your capacitors, you need to check the voltages between each phase of the motor. The 3 phases used by the motor are A-B-C, or also refered to L1-L2-L3. To check the phase voltage, place each probe from a voltmeter on the respective phase. Phase A-B (Phase A to B) will be 240 volts, which is the line voltage of your house. One of the phases will be low, and the other will be high. You will need to adjust the capacitors until these voltages get close to being balanced out. If you find one of these voltages extremely high, turn the motor off immediately. There are some configurations where one phase’s voltage can exceed 350 volts. This will put high currents through the motor, and that is not good. Forgetting to turn your start circuit off is one example of this.

To determine the best configuration of a phase converter, I have found it best to create a data table and write down the various values. I first vary one capacitors size larger and smaller from the initial configuration. Then I vary the other capacitor. You should be aware that when you connect a new capacitor to one which was just powered, there will probably be some sparks as one capacitor charges up the other. This is disconcerting, but it is normal. Make sure you turn off the power before rearranging the capacitors.

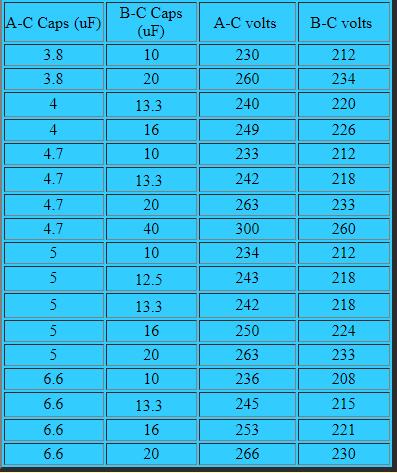

The data table below is from a lathe.

To see this data better, I have created a graph which shows the relationship between the two voltages. Graphing the data isn’t necessary, nor did I use this, but it may help you see how different configurations effect the outcome.

From the data table and chart, there are a couple of configurations which work fairly well. Notice that at no time do all three phases reach 240 volts. This would be a perfect conversion. The best I could attain was 240 volts from (A) to (C) with 220 volts from (B) to (C).

These are the conditions I looked at when selecting the capacitor sizes:

- I wanted the phase voltages to be as close to being equal as possible.

- I did not want any voltage to exceed 240 volts.

- While still adhering to items 1 and 2, I wanted to use the least number of capacitors.

With respect to item #3, even though the motor performance was best when using 4 uF and 13.3 uF, this required 8 capacitors to achieve this combination. Since the performance when using 5 uF and 12.5 uF capacitors wasn’t much different, I chose this combination. This decision was made after the testing, when I returned to the store and located 5 uF and 12.5 uF capacitors. (I want this phase converter to be small enough to fit in a junction box bolted to the inside of one of the legs.)

Configuring the Starting Circuit

The purpose of the starting circuit is to get the motor up to speed as fast as possible. The longer it takes to get the motor up to speed, the longer high currents will be present in the motor’s windings. For the most part, the larger the starting capacitor, the faster it starts.

Manual on/off Switch

The simplest method for engaging the starting circuit is the use of a standard on/off switch. This requires the operator to turn the switch on before starting the motor, and turning it off after the motor is up to speed. The drawback to this, is that it requires the operator to activate and deactivate the switch. Failure to do either of these will result in excessively high currents in the motor.

Momentary Pushbutton

The momentary pushbutton is better, since you can’t forget to turn your start circuit off when the motor is up to speed. With this, the start circuit is only engaged for as long as you hold the switch in. The drawback, is that the switch can be released too soon, before the motor gets up to speed. This would result in high currents flowing through the motor unless the start switch was again pressed. And if the switch was not released on time, currents would again be high after the motor gets up to speed.

Off-Delay Timer

With most switches and relays, when you tell them to turn off, they turn off. With an off-delay timer, when you tell it to turn off, it hesitates for a little bit before it turns off. This is ideal for a starting circuit, where we only need it to be active for a second or so. With an off-delay timer, we would use the momentary push button to activate the relay, and releasing the button would activate the timer.

The benefit to this setup is that you can’t forget to turn the starter off, yet it will always remain active long enough to get the motor started. The drawback to this setup is almost trivial. If the timer is programmed too long, then the starter will remain active slightly after the motor is up to speed. Unless you had a method for sensing the actual speed (RPM’s) of the motor, this is the most foolproof method for operating the starting circuit.

Current or Voltage Sensing Circuit

How this works, is when pressing the normal start button on the lathe, the starting capacitors are already engaged. As the motor comes up to speed, a relay senses the increase in the third phase voltage. As this relay becomes active, it opens a switch, which disconnects the starting capacitors. As a side effect, if I grab the hand wheel and slow the motor down, the starting circuit re-engages to bring it back up to speed. This is what made me decide to make the unit self-starting. Before completing the self-starting aspect of the converter, we loaded the motor just to see how much power it was getting.

When the lathe was set for low speed, the motor came up to speed quickly, as it’s load was low. When the lathe was set at a higher speed, inertia made the lathe start slower, and it took longer to come up to full speed. This circuit compensated for the longer start-time, and remained engaged for a longer period of time.

Initial Concept: While we fine tuning the phase converter’s capacitors, we noticed that the voltage from line 2 to the generated line 3 started out at 16 volts before we started the motor. As the motor came up to speed, this voltage gradually increased until it reached its final value of 220 volts.

Relay: The relay uses the normally closed contacts, which means that when there is no power to its coil, the contacts are touching. The relay’s coil is rated for 120 volts at 60 Hz (AC power).

Variable Resistor: The variable resistor acts as a fine tuning control. Some of the circuit’s voltage is expended across this resistor. By adjusting the amount of resistance in the dimmer, you control how much voltage the relay gets.

As we adjusted the dimmer, the starter control would either turn off too soon, or not at all. By making these adjustments, we controlled how long the starter remained active with respect to the motor’s speed.

The Rotary Phase Converter

With the discussion above on the static phase converter, there isn’t much to explain about the rotary converter. The rotary converter is nothing more than a second motor in the circuit which is acting as a generator. With the static converter, the tool’s motor performed this function, but at the cost of some loss of power. With the rotary converter, the idler motor is under no physical load, but it cleans up the signal a little. If you examine the drawing below compared to the first drawing, the only difference is that we added the idler motor.

The output of the rotary phase converter is closer to being a true 3-phase source than the static converter. This provides more power to the tool motor, and also brings it up to speed faster. The rotary converter is best served when you have a motor which is started and stopped frequently, and you need the full power of the motor. Furthermore, a single rotary converter can drive several different 3-phase tools.

Setting up the rotary converter is the same as the static converter described above. The only decision to be made is the size of the idler motor. The idler motor needs to be larger than the largest tool which will be operated.

Since the static converter will provide a motor with 80% of it’s normal operating power, and the rotary phase converter uses a static phase converter as a starter, your idler motor should be 125% of your tool(s) motor size. That is, if your tool is a 5 horsepower motor, your idler should be between 6 and 7 horsepower. It is always better to err on the high side, so I would use a 7 horsepower idler motor. If the converter will operate more than one tool, make sure the current rating of the idler motor is 125% of the sum of the tool motors.